Protective Coating for Multifunctional Applications – with a focus on what matters most

The upper surface of a plant’s leaves is its outermost defence, not only protecting it against pests and water loss, but also helping shake off dirt or increase resistance. This is a particularly well-known characteristic of the lotus flower: Water just drips right off its leaves. This was the biological inspiration behind innovative, self-cleaning surface coatings with what is known as the “lotus effect”.

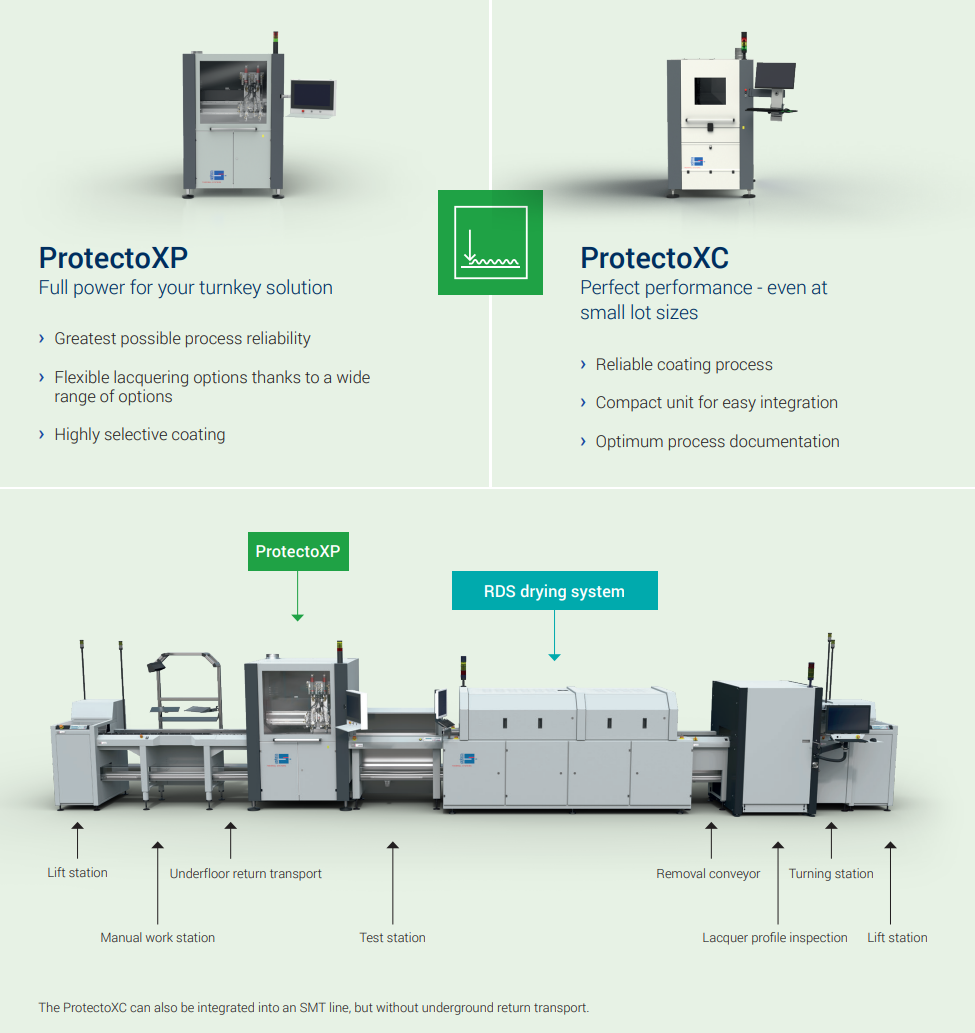

The protective lacquer coating on electronic units acts in a similar way. Our coating systems ProtectoXP and ProtectoXC protect sensitive components so that aggressive environmental influences such as moisture, corrosion, chemicals, dust or vibration simply drip off. High-selectivity conformal coating is the key to ensuring electronics work reliably and is indispensable in modern manufacturing. The use of protective lacquer coatings makes perfect sense for conserving the functionality of circuit boards over a long period. Fields of application range from offshore wind farms through shipbuilding, military hardware, telecommunications, medical technology, industrial control and automotive systems to electronics in private households.

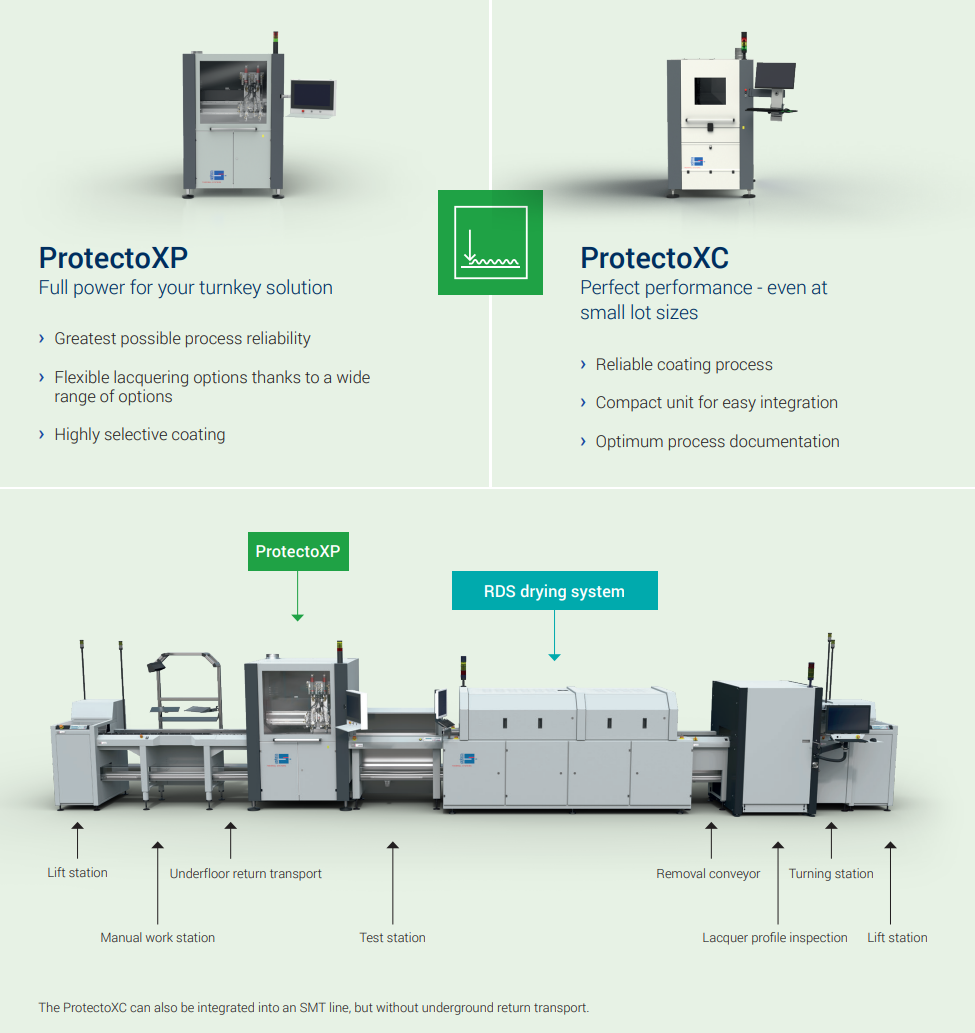

The Protecto series at a glance

Strong in the process – the coating systems from Rehm

Would you like to combine optimal coating solutions and reliable drying methods in your manufacturing process? Are you looking for a high-performance facility that can be smoothly integrated into small production spaces, perfectly suited for coating small batches and requiring only manageable investment costs? The coating systems from Rehm impress with their process reliability – for large and small lot sizes. Our conformal coating concept consists of the Protecto coating unit and an RDS coating dryer, including handling based on customer specification.

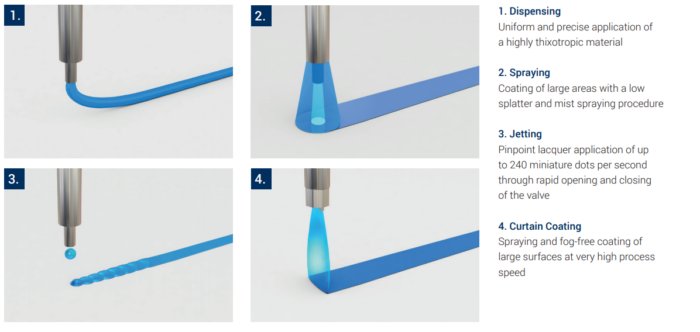

Safe and accurate to the result material application

Protecto meets your requirements for the highest quality, stability and productivity in automatic inline coating services. With up to 4 coating applicators, you can synchronise several modules simultaneously in master-slave mode to apply the coating or directly apply with up to 4 different materials without set-up time.

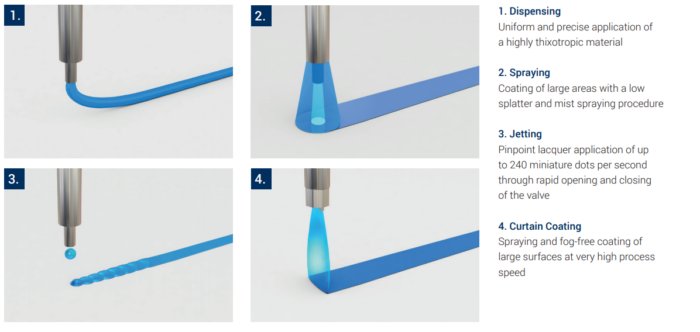

At the heart of the Protecto is coating management working in tandem with nozzle technology. Up to two coating applicators can be used – with a wide range of possibilities. The same nozzle can be used to switch between dispensing, spraying and jetting procedures “on the fly”. Parts which are

high up or close together are easy to reach thanks to the slim nozzle design with only 2.4 mm and a length of up to 100mm. If necessary, parts can be flushed from below due to the

patented Vario Coat nozzle, ensuring that hidden ports.

All-in-One Coating

The patented Stream-Coat® nozzles are compatible with all conventional coatings, from low-viscosity to high-viscosity. With Protecto coating systems you can carry out the various

selective application procedures of dispensing, spraying, jetting and curtain coating, “on the fly”. An implicit air nozzle precisely dispenses the coating and distributes it with little

splatter or mist. The homogeneous film of coating can, with the aid of the adjustable airstream, even be applied under or behind adjacent component pins and in shadow zones

without the need to tilt the applicator.

The application determines the equipment – Variety of coating applicators

We have the right equipment for every individual process. Our broad portfolio of paint applicators allows a variety of applications. Both proprietary developments come into play

as well as applicators from suppliers who have already established themselves in the market. Various options such as material needles, patented two-material nozzles and material warmers, are available for the respective applicator. Thus, the plant equipment can be selected using a wide range of different accessories that provides the best combination of cost-effectiveness and process performance.

Greatest possible process reliability with innovative options

When it comes to coating, one thing is essential: precision. Protecto systems are designed to ensure that the required volume of coating is always evenly applied, whether through a pressure valve, a cartridge or a pump from the original container. Automatic needle measurement checks the target position of the applicators in freely definable cycles and if necessary corrects the coating program automatically. The dispensing of the coating is controlled by the software, which loads the appropriate coating program with the suitable coating and nozzle type. An optional heated nozzle keeps the protective coating always at a constant temperature and thus a consistent viscosity regardless of environmental conditions. A specially developed coating lance with a level indicator prevents bubble formation when changing the coating.

For absolute process reliability Protecto systems are optionally equipped with a fiducial camera. This means the coating program can be corrected and coated in the correct position by registering the marks even if a board is laid into the flight bar inaccurately. A barcode checks whether the set coating program is right for the assembly in place. If

there is a deviation the process is automatically blocked.

A high-precision weighing cell is optionally available for the Protecto systems, which compares the weight of the paint applied by any given applicator with a previously defined

setpoint value and provides the user with corresponding feedback in the setup mode as well as cyclically during series production. As a result, errors in the fluid circuit can

be easily and efficiently detected, and eliminated without delay. The acquisition of weight data, as well as configuration and adjustment, are software controlled and can be

individually adapted.

More than “just” coating – Application possibilities with ProtectoXP/XC

With the Protecto systems, completely new application fields are emerging – even outside of the conformal coating sector. Thanks to the highly flexible system construction, you can

use ProtectoXC to combine for three and ProtectoXP for four processes within one machine.

In addition to sealing the entire circuit board, partial areas or individual components can also be coated on the support. With innovative nozzle technology, the user can apply a wide variety of materials to the module – so each product will be optimally protected later according to the requirements.

- Dam & Fill 3D-Application

- Sealing

- Globe Top

- Flip Chip Underfill

- 2K Encapsulation

- Heat Dissipation

- Individual Requirements

Smart software for efficient processes

With ViCON, Rehm offers the optimal software solution for its systems – ECAD data import

possible with ProtectoXP and ProtectoXC

A variety of analysis tools, more productivity, efficiency, flexible working and the highest quality: With ViCON, Rehm Thermal Systems has designed and created software that meets all the requirements of modern, networked, and above all, future-orientated electronics manufacturing. Alongside the use of touch operating elements and gestures, the new organisation of menu options and control panels, the core feature of ViCON software’s development lies in the option of accessing the software from a variety of devices. The ProtectoXP and ProtectoXC dispensing systems are equipped with the ViCON Protecto system software and have numerous features for easy program creation for reproducible coating results.

Following the successful introduction of ViCON for Rehm’s reflow convection soldering systems, the software has now been specially adapted to the requirements of the ProtectoXP and ProtectoXC dispensing systems. The main feature of ViCON Protecto is the option of importing ECAD data and image files directly and optimising ECAD data for the coating process by cutting. The integrated camera also enables stitching: A complete image of the printed circuit board can be created and further processed from several

individual images. While the program is being created, the user is supported by a wizard that shows the user all current progress by means of colour-coded pointers, and thus easily

facilitates usability.

After selecting an applicator, users can access a coating database via ViCON Protecto that has been filled by the application specialists of Rehm Thermal Systems and contains all the important coatings with their parameters. ViCON Protecto enables programs to be created offline, which can be used simultaneously with the current production process. With the camera integrated into the Protecto coating systems, ViCON software can be used to read both fiducials as well as (data matrix) codes (DMC).

The objective of ViCON Protecto is to configure the system’s current operating status clearly. The operator can react quickly and intuitively to status and alarm messages. At the same time, access rights, views and favourites are tailored to each user. The specifications of ViCON Protecto are based on the basic elements of ViCON, which have already performed impressively in the convection soldering systems of the Vision series. Thanks to colour coding, the operator can also easily identify and assign the status of the display from a greater distance. ViCON software is also consistently designed to accommodate multiple languages. The simplicity with which you can switch “on the fly” to the preferred language simplifies worldwide remote access to other Rehm systems and operating in an international environment. Alarm messages can be clearly viewed, interpreted, edited

and processed at the top of the screen – the relevance of the alarms is displayed in different colours. To control the system individually, the operator can individually create a

favourites bar, that includes relevant and necessary parameters and control elements. These then appear on the main screen and at a definite point on each page.

Process locking and traceability – for a detailed process documentation

Depending on the production environment, the Protecto systems can be optionally connected to an MES in various ways. Any combination of the various configuration stages

of production data acquisition (PDA), traceability, process locking and material locking ensures flexible production.

The Protecto systems can be optionally connected to a line master computer or an MES. Depending on the configuration, various data is communicated between MES and ProtectoXP/XC. An interface specially designed by Rehm (ROI – Rehm Open Interface) is used. On the one hand, this means a high degree of standardisation; on the other hand, customer-specific adaptation can be carried out without problems. To identify the module, an ID-reader (bar code, DMC, RFID) is installed on the conveyor belt in front of the system and connected to the Protecto control.

Alternatively, the barcode can also be transmitted via the Hermes interface. Optionally, the identification can also be carried out via the MES. This ensures absolute process reliability through process locking and can guarantee seamless documentation by means of unique data records for each module.

MES-components:

- PDA

- Trace Data

- Process Locking

- Material Locking

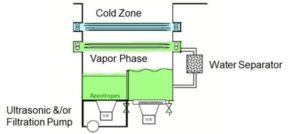

Reliable process – for cleaning and maintenance

Rehm has developed a ground-breaking cleaning system for Protecto systems which is particularly maintenance-friendly. A brush station with a solvent bath allows optimum cleaning of the lacquer nozzles. Even if the system has been off for up several days – depending on the used material – it is operational at the touch of a button without additional cleaning work. The cleaning tank protects nozzles, cables, connections and ports from drying out and automatically cleans the system during downtime, without wasting resources.

This allows long processes to run without requiring maintenance. Depending on the materials even long downtimes without cleaning and flushing the valves or system are possible. All control elements and lacquer stocks are easy to access for the performance of maintenance tasks.

Optimum assembly protection without contamination of the work environment

To prevent contamination from vaporised solvents of lacquers and compounds in the immediate vicinity of the Protecto systems, the lacquer supply is integrated in the system at the back of the plant. This means there is no odour pollution from random releases of solvent vapours into the environment. The plant also has an extractor system which conducts and removes solvent-containing evaporations to the in-house exhaust system during the coating process.

View Rehm ProtectoXP, here.

Protective Coating for Multifunctional Applications