Sustainable and Economic Technology: Precision Cleaning

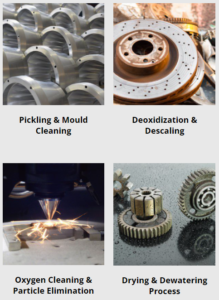

Precision cleaning is a surface treatment process that removes contaminants from a surface at a micro-level. Failure to remove contamination at the micro-level can impact product reliability and performance.

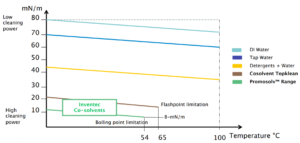

Surface Tension of Cleaning Agents

Solvents have much less surface tension than detergents, which in turn offers high cleaning power. Lower surface tension offers higher wetting power, which allows solvents to deep clean in micro areas, such as blind holes, or under surface mounted components.

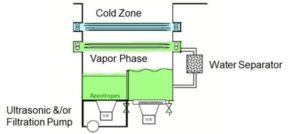

Concept of Vapour Degreasing

In a basic configuration, there are 2 sumps inside a vapour degreaser. The first sump boils the solvent and creates the vapour phase. Then, cooling coils catch pure vapour and condensate back to the rinsing sump through a water separator.

With this method, the rinsing sump remains clean, meaning that the vapour degreaser is actually recycling solvent while it is running. Ultrasonic generators can be attached to both sumps to give additional agitation.

Benefits of Vapour Degreasing

– Better cleaning results

– Shorter process time (typical dry-to-dry cycle within minutes)

– No cross-contamination

– Lower energy usage

– Less waste disposal costs

– No water consumption

– Lowest possible post-cleaning residue

What about the Environment?

In the early 1990s, with the implementation of the Montreal Protocol, aqueous systems were favoured to eliminate ozone-depleting solvents such as CFC-113, HCFC-141b and 1,1,1-trichloroethane.

New technologies, such as non-ozone depleting and VOC-free solvents are now available, helping to protect our water usage and the ozone layer.

Together with the improvements in equipment design, vapour degreasing is a much more environmentally friendly process

Learn More – Ozone Depleting Substances