MUNICH, Germany – This year’s Productronica in Munich made it clear that electronics manufacturing is entering a new phase defined by intelligent automation, practical AI integration, and the rapid rise of credible mid-tier equipment suppliers from Asia. What stood out most for markets like Australia was the strong emphasis on high-mix, low-volume production. Exhibitors showcased flexible, software-driven systems designed for fast changeovers, minimal operator dependency, and precision repeatability. For countries and companies operating in specialised, small-batch environments, this shift signals a major advantage. The global industry is no longer optimising solely for scale. It is building solutions tailored to exactly the kind of manufacturing landscape where many of our customers already excel. Peter Ruefli, our Managing Director, has returned with some fresh views of the trends shaping our industry.

A Resilient Market with an Appetite for Innovation

Despite ongoing market headwinds, the atmosphere across the exhibition floor was overwhelmingly positive. Our supply partners reported a strong flow of enquiries and extremely high levels of engagement , signalling a clear appetite for investment in new technology.

One of the most telling indicators of this momentum came from our partner, Rehm Thermal Systems, who registered over 500 qualified leads, a remarkable result that proves the industry’s focus on adopting smart thermal solutions. This years’ Rehm Thermal Systems focus was on energy-efficient reflow, advanced vapour-phase soldering, and flexible selective-coating technology. Their newest coating and curing innovations were positioned for high-mix, low-volume manufacturers needing precision, consistency, and quick changeovers.

Beyond the Buzzwords: Automation is the New Standard

A notable shift at this year’s event was the evolution of the conversation around Industry 4.0. The term itself was less prominent, not because it has lost relevance, but because its principles are now deeply embedded in modern manufacturing. Data-driven automation, interconnected systems, and advanced sensor integration are no longer futuristic concepts but foundational elements of a competitive production environment. Artificial intelligence (AI) continues to be a major driver of this evolution, with several exciting announcements pointing to its growing practical application.

Key Technology and Partner Highlights

Our time at Productronica was also an excellent opportunity to connect with our partners and witness their latest innovations firsthand.

Viscom’s AI-Powered Inspection: A significant announcement came from Viscom, who will be launching their vAI-Provision software in March 2025. This update introduces long-awaited virtual programming assistance for their AOI systems, promising to dramatically reduce programming time and enhance inspection precision. We will keep our customers informed as the release date approaches.

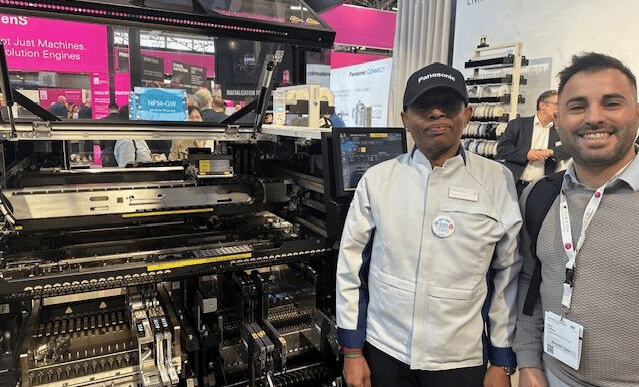

Panasonic’s Advances in Automation: Panasonic Connect showcased several impressive technologies. Their new auto-setting feeders, which allow for the loading of component tapes up to 104mm wide while the machine is in operation, offer a significant boost to efficiency and reduce downtime. Additionally, the compact NPM-WF Inserter provides a powerful solution for automating manual insertion processes, enabling manufacturers to gain a competitive edge without sacrificing valuable floor space.

Strategic Developments in Materials and Coatings

The materials sector also saw significant developments. Following its acquisition, Chase Corporation is undergoing a strategic consolidation of its Humiseal distribution network in Europe, reducing from over 40 sites to just 10. We are proud that our Zurich-based partner, Finn Technologies & Partner GmbH, has been retained as a key distributor for the German-speaking regions, where they will continue to lead technology seminars on advanced coating materials.

It was also a pleasure to connect with Jean-Pierre Duchi, Managing Director at AB Chimie, which is now part of Chase Corporation. Their new UV 800 LED coating, recently approved by Siemens, is already making waves. Its ease of application, exceptional clarity, and excellent edge coverage at low viscosities make it a standout product for demanding applications.

A New Partnership for the Australian Market

Finally, we are thrilled to officially announce our new partnership with Photonics Systems Group. As their official distributor for the Australian market, we will now offer their cutting-edge solutions in wafer trimming, photovoltaics, and laser applications. This collaboration will significantly strengthen our Microelectronics division, particularly in providing advanced laser cutting, marking, and resistive trimming for PCBA.

We were delighted to meet with Eckhard Schaefer, Senior Vice President of Sales for Asia, to finalise the agreement and look forward to a successful journey ahead.

Looking Forward

Productronica 2025 has reaffirmed that our industry is not just talking about progress—it is actively making it happen. From smarter automation and practical AI tools to innovations in materials science, there is real momentum shaping the future of manufacturing.

At ONBoard Solutions, our commitment is to help our customers harness these innovations to improve their processes, enhance performance, and maintain their competitive edge. We look forward to supporting more businesses as these exciting technologies become available in the Australian market.