Seamark X5600 Offline X-Ray Inspection Machine

Seamark X5600 Offline X-Ray Inspection Machine: Precision and Efficiency

The Seamark X5600 Offline X-Ray Inspection Machine is a compact and precise micro-focus X-Ray inspection machine suitable from R&D, to laboratories and production. It stands as an excellent economical choice for inspection of all common electronic components, and other devices.

IC Chip Inspection: The Seamark X5600 Offline X-Ray Inspection Machine excels in non-destructive testing, particularly in prospectively testing internal defects of IC chips. Leveraging its advanced X-Ray tube, this inspection machine emits X-Rays to illuminate IC chips for imaging. The digital tablet captures the signals, transmitting them to a computer for real-time imaging on the screen. This non-destructive testing method allows tested samples to be reused, effectively saving production and inspection costs.

Key Functions of Seamark X5600 Offline X-Ray Inspection Machine:

- Automatic Void Ratio Calculation:

- Streamline your process with automatic void ratio calculation for efficient and precise inspections.

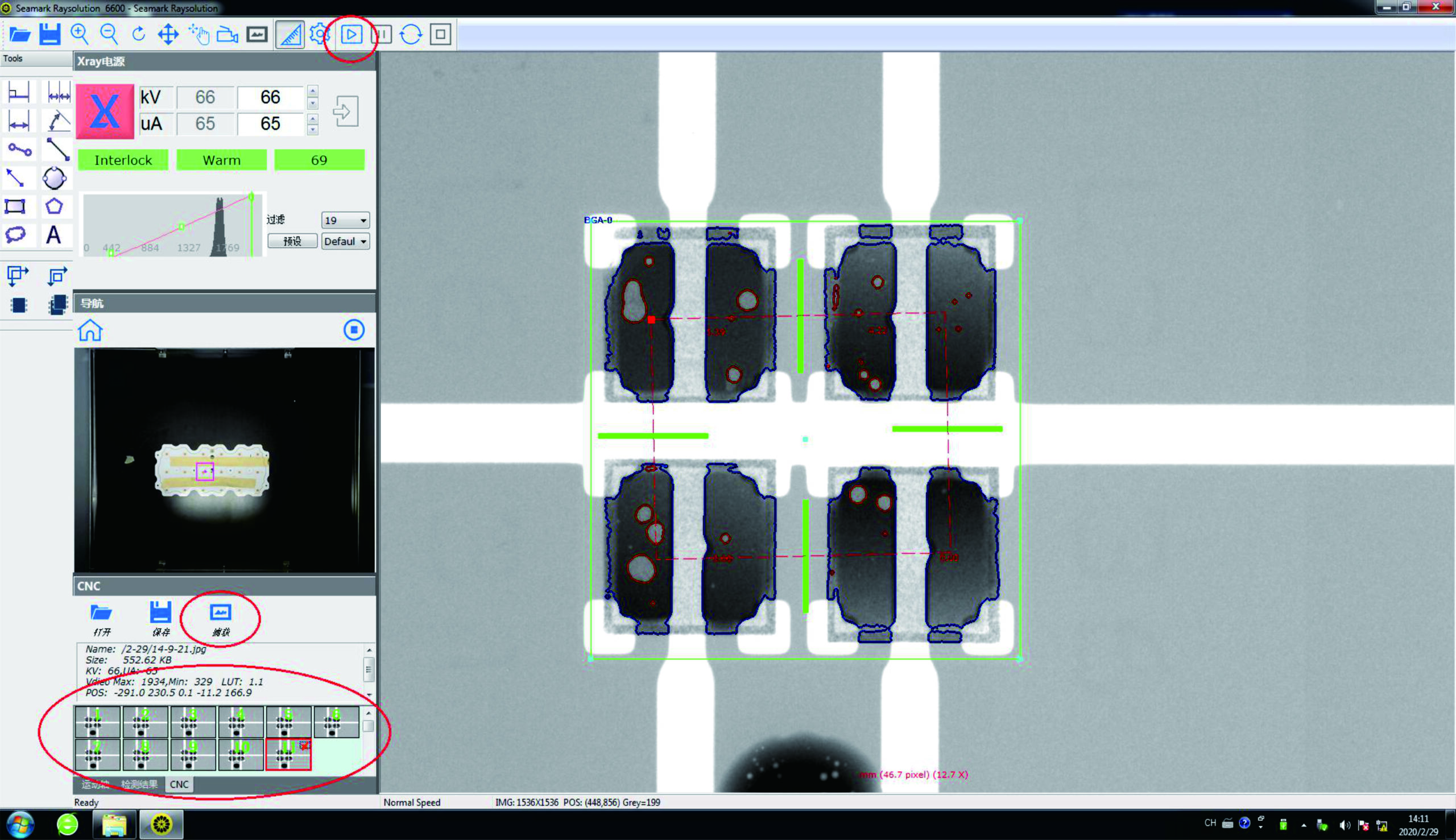

- Enhanced BGA Inspection:

- Quickly select and mark single solder balls or inspect entire matrices with ease. The Seamark X5600 Offline X-Ray Inspection Machine ensures accurate and reliable results following system guidelines.

- Size Measurement:

- Utilise measuring tools for distance, ratio, lines, angles, and more. Customise with text descriptions for comprehensive size measurement.

- Defect Inspection:

- Automatically detect defects such as size, area, broken wires, and bridging. Customise image algorithms based on product features for fully automatic defect inspection.

- CNC Inspection:

- Benefit from CNC multi-point automatic inspection, supporting batch inspection with automatic image saving and report generation.

- Tilt/Rotate Function:

- The X5600’s tilt angle inspection function supports ±30°, allowing for multi-angle observation. The 360° rotating photo inspection function ensures a comprehensive view with no dead angles.

Advantages:

- Miniaturised design for easy installation and operation.

- Applicable to various applications, including Chip, LED, BGA/CSP, Wafer, SOP/QFN, SMT, PTU packaging, Sensors, Connectors, and Precision Castings inspection.

- High-resolution design for rapid image acquisition.

- Infrared automatic navigation for quick shooting location selection.

- Simple software operation, ensuring low operating costs.

- Long lifespan, guaranteeing lasting performance.

Invest in the Seamark X5600 Offline X-Ray Inspection Machine for precision, versatility, and cost-effectiveness in your X-ray inspection needs.

Other Seamark models are available. To see more solutions from Seamark, click here.

To learn more about Seamark, click here.

Seamark X5600 Offline X-Ray Inspection Machine

$0.00

Seamark X5600 Offline X-Ray Inspection Machine: Precision and Efficiency