High-performance equipment that delivers high-quality results!

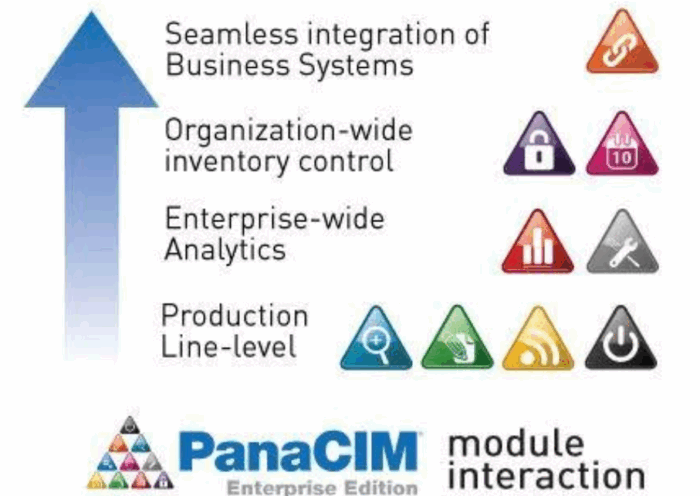

PanaCIM Gen 2 Enterprise Edition effectively delivers a feature-rich, manufacturing software suite through a scalable, small-footprint appliance that can grow with the manufacturer, while providing unprecedented integration of Panasonic and best-in-class, complementary technology partner equipment.

Developed from a history of proven industry excellence in SMT & 100,000+ solutions installed!

A locally-developed Manufacturing Execution System (MES) sustained by an extensive global support infrastructure, cost-effective PanaCIM Gen 2 Enterprise Edition solutions ensure manufacturers can focus on their core competencies, while Panasonic software supports the enterprise.

Scalable Solution – Modular design allows you add over time as demand changes

Connect with External Systems – Fast implementation and open-source allows for seamless PanaCIM integration

Ensure Quality Enforcement – Improve quality control with less defects and reduced scrap and rework

Single Solution – Handles all MES functions at line and floor levels, supporting Panasonic and partner equipment

Centralized Warehouse Data – Provides options for long-term storage and data analytics

How PanaCIM Works

- Begin with Production Planning to determine production resources’ acquisition and allocation as well as satisfy manufacturing requirements accurately and efficiently.

- Then manage inventory and assets, monitor MSD exposure, analyze relative performance, and reduce inventory costs with Material Control.

- Use Material Verification to validate that the correct components are loaded-increasing quality and decreasing waste. It also eases changeover, splicing, and parts exhaust.

- When production starts, centralized monitoring and notification from Production Monitoring and Dispatch allows your team to be fully engaged in events as they occur on the floor.

- Configure and automate line changeover with Product Changeover and Control for quick and correct product download and equipment preparation without human intervention or downtime. Use Enterprise Link to seamlessly connect data from PanaCIM Enterprise Edition with other factory systems such as MRP/ERP systems for efficient, increased data integrity.

- Maximize throughput with centralized maintenance scheduling, work order management, and logging of equipment resources through Maintenance. Organizations can minimize risk to recall, defects, or regulatory issues by viewing Panel, Component-to-Panel, and Placement-to-Panel traceability through the Traceability module.

- And factory performance can be monitored anywhere in the world with Production Analysis, a web-based application operating in real-time with historical comparison, which also allows hastening of corrective response and increased productivity.